SMT/DIP Production Lines

Surface Mount Intelligence

- High product consistency

- High reliability

- Auto welding

- Cost and time saving

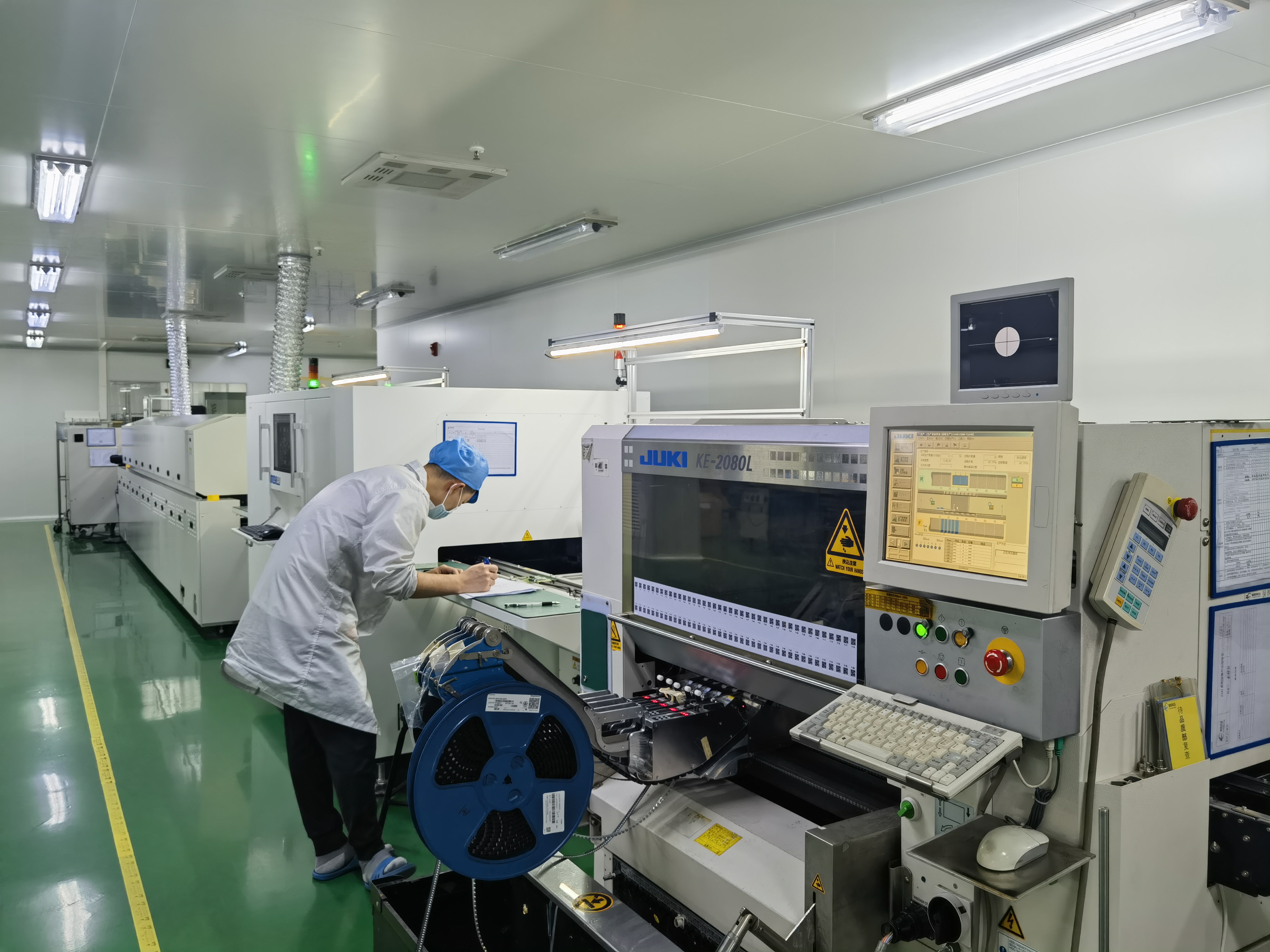

JUKI SMT Production Line

-

Number of production lines

8 -

Max PCB size

410*340mm & 1200*340mm -

Min. PCB size

50*50mm -

SMT Min. component size

0201 -

Placement positioning accuracy

±0.03mm -

Min. pitch for IC

0.2mm -

Min. pitch for BGA

0.25mm -

Double-line common reflux furnace by transfer machine

EUROPLACER SMT Production Line

-

Number of production lines

4 -

Max PCB size

910*600mm -

Min. PCB size

50*50mm -

SMT Min. component size

01005 -

Placement positioning accuracy

±0.02mm -

Min. pitch for IC

0.15mm -

Min. pitch for BGA

0.2mm -

Double track nitrogen reflux furnace with generators

-

Auto batching storage system and intelligent storage

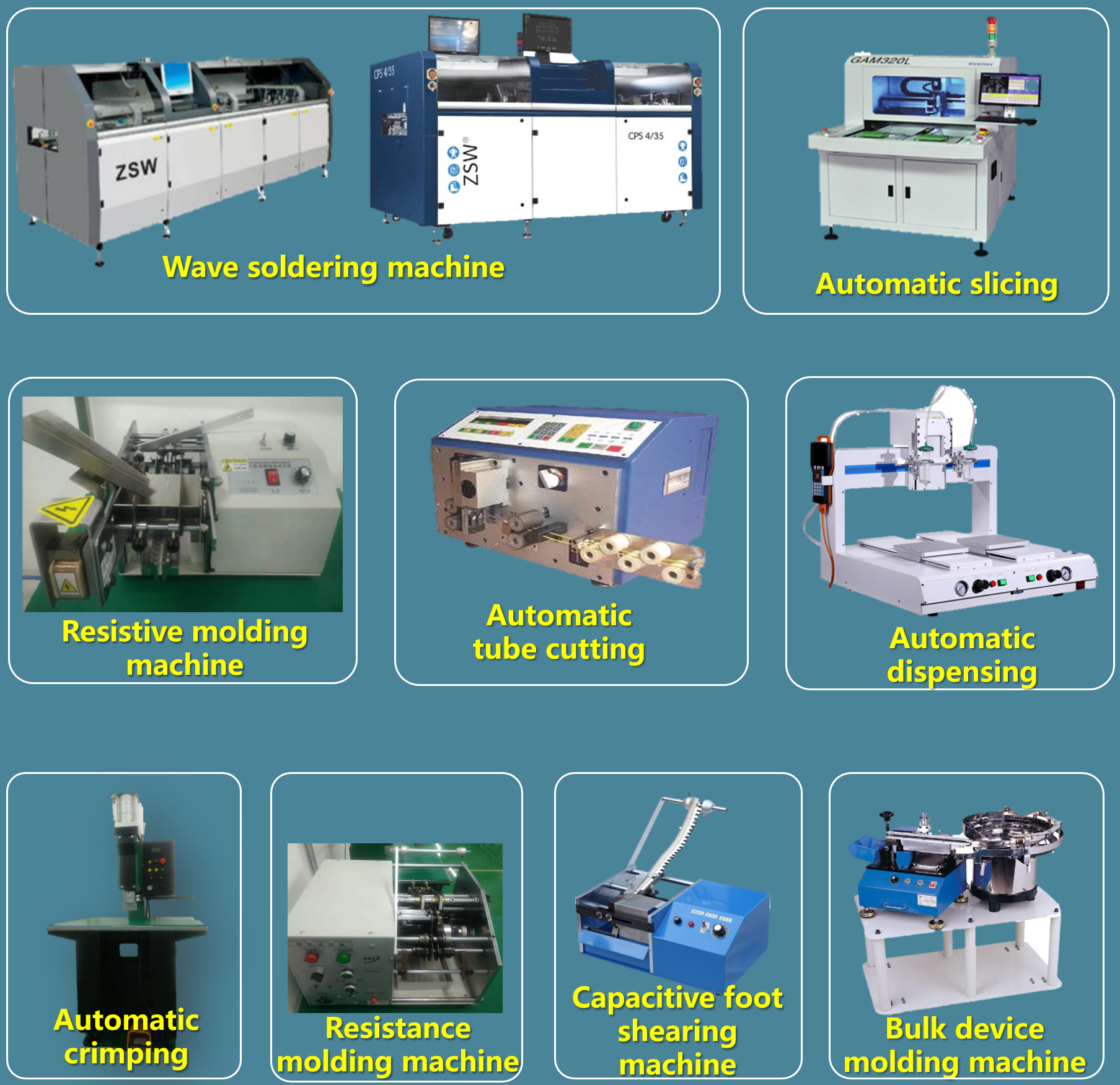

DIP Line Parameters

-

Track Adjustment Width

510mm -

Max soldering temperature

330℃ -

PCB transmission speed

0.2~10m/min -

PCB positioning accuracy

±0.2mm -

Weld positioning accuracy

±0.15mm -

Tin pot heating time

75min(to 280℃)